Consult local building regulations before installation.

Familiarize oneself with the installation operation guide.

Ensure that you have all the necessary tools and materials listed on the instruction sheet.

For each product, please refer to the installation guide for prompts.

When transporting Hualong plastic wood flooring, please support it to the edge for better support.

Place on a flat surface and cover with opaque materials.

Do not stack Hualong plastic wood materials arbitrarily when unloading.

Maintenance and Handling Guidelines for Floors:

Scratches, cracks, and grooves should be minimized to protect the aesthetics of Hualong plastic wood flooring. Please follow the following guidelines:

When spreading the flooring material, avoid sliding and rubbing against each other. When spreading out from the entire pile, it should be lifted and placed again.

Do not let tools or towing equipment slide on the floor surface when constructing the floor.

Avoid contact between the floor and construction waste.

Important information:

When using Hualong plastic wood products or any building materials for work, it is necessary to ensure proper clothing and equipment safety.

According to the instructions applicable to the manufacturer, standard wood working tools are available for Hualong Plastic Wood products, and fragments can be discarded together with general construction waste.

Hualong plastic wood flooring has a built-in hidden buckle system and is easy to install

Hidden buckle guide:

Use small # 8X2-1/2 "high-quality plated stainless steel or composite floor screws

Pre drilling should be completed in low cold weather conditions and within 1-1/2 "of the end of the wooden board

Do not use glue or sealant to secure the connection between Hualong plastic wood flooring, sealed flooring, and any other surface. Because this will be detrimental to the natural thermal expansion and contraction of the floor, and will hinder floor drainage.

Appropriate ventilation methods are also necessary

In order to reduce moisture under the floor, a minimum of 12 "high unobstructed continuous airspace must be left along the three sides of the floor to create a cross ventilation path, which must be placed directly below the floor keel.

In some limited use cases, including wooden boards that support internal corner buildings, additional ventilation equipment is necessary to ensure that the floor meets the building's needs.

Improper ventilation will cause damage to the floor surface and render the guarantee ineffective.

Important information:

In special circumstances, engineering inspections and/or reduced spans may be required. Please consult local building regulations frequently.

Hualong Plastic Wood Flooring Installation Guide:

Tools required for installation:

Standard tools: Basic tools such as chainsaws (desktop, handheld), electric drills, windbreakers, etc.

Engineering construction tools: level, tape, plumb bob and other engineering construction tools.

Installation diagram of stainless steel buckle:

Design a plan based on the construction intention, and budget the required materials by developing a design plan to save construction time and costs. Due to the wide variety of options available for Hualong Plastic Wood, material selection can be made according to customer preferences.

During the construction of Hualong Plastic Wood, woodworking machinery can be used for cutting, sawing, drilling, etc.

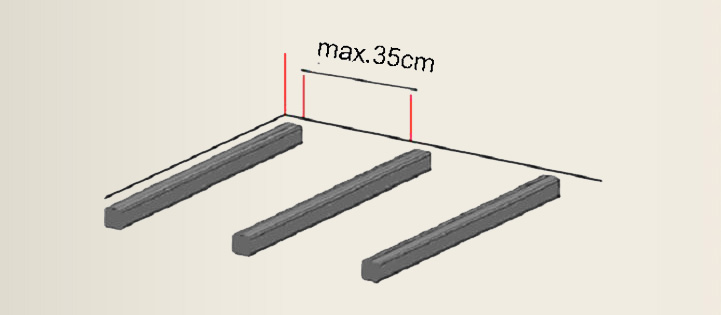

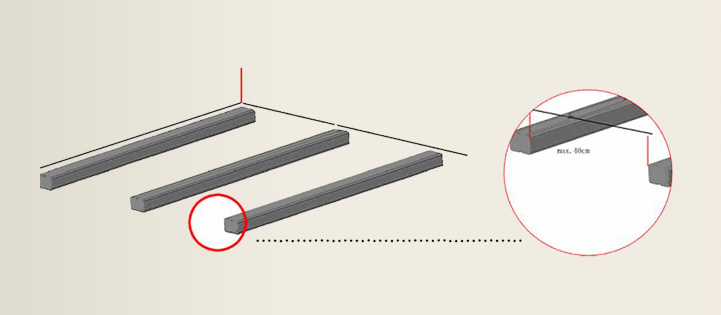

When installing the floor, the first step is to harden the ground and then fix the keel on the hardened ground. We recommend a keel spacing of 35-40cm. The spacing between keels can also be shortened according to requirements.

When installing the floor, a distance of 3cm from the building should be considered.

3. The connector of Hualong plastic wood flooring is a stainless steel buckle. To increase the gripping force of self tapping screws, the diameter of the drilled hole should be less than 3/4 of the screw diameter.

4. In specific construction, a rubber hammer should be used to gently tap the floor to ensure even gaps and the overall appearance of the construction surface.

5. Due to the large construction area, which affects the length of the board, when cross sections are required, the recommended spacing between sections is 5mm.

6.When the keel and floor cannot be connected with buckles, self tapping screws can be used to connect between the floor groove and the keel.

7.Ê©č€Íê±ÏșóŁŹžùŸĘ”Ű°ćșÍÁúčÇ”ÄĐÍČijߎ磏ѥÓĂÏàžš”Ä·â±ß°ćœűĐĐ·â±ßĄŁ

2. ”Ű°ć°ČŚ°Ê±ŁŹÒȘżŒÂÇÓ뜚ÖțÎïÓĐ3cm ”ÄŒäŸàĄŁ

4. ÔÚŸßÌćÊ©č€ÖĐÓŠÓĂÏđÆ€Žž¶Ô”Ű°ćœűĐĐÇáÇáÇĂŽòŁŹÒÔ±ŁÖ€Œä϶”ÄŸùÔÈșÍŐûžöÊ©č€Ăæ”ÄĂÀčÛĄŁ

7. Ê©č€Íê±ÏșóŁŹžùŸĘ”Ű°ćșÍÁúčÇ”ÄĐÍČijߎ磏ѥÓĂÏàžš”Ä·â±ß°ćœűĐĐ·â±ßĄŁ

Ê”ĐĔ۰ć”Ä°ČŚ°Łș

2. Ê”ĐÄ°ćÔÚ°ČŚ°Ê±ÓŠżŒÂÇÓ뜚ÖțÎïÓĐ3cm ”ÄŒäŸàĄŁÊ”ĐÄ°ć°ČŚ°Ê±ĐèÓĂĂś¶€œűĐĐ°ČŚ°ŁŹ¶€ŚÓλÖĂÓŠÓë°ć”ıßÔ”ÎȘ2cmĄŁ

3. žùŸĘ”Ú2 Čœ”ÄÊ©č€ÒȘÇóŁŹÒÀŽÎœűĐĐÆÌŚ°ĄŁ

4. Ê©č€Íê±ÏșóŁŹžùŸĘ”Ű°ćșÍÁúčÇ”ÄĐÍČijߎ磏ѥÓĂÏàžš”Ä·â±ß°ćœűĐĐ·â±ßĄŁ